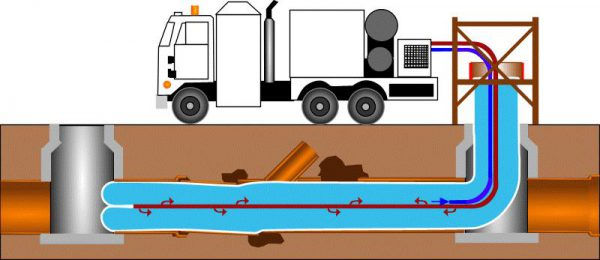

CIPP (Cured In Place Pipe) technology, also known as trenchless technology or in-situ pipe repair, enables the restoration of damaged sewer systems without the requirement for excavation or trench digging. This process involves deploying CIPP tubes using water, steam, or air pressure to line the existing pipes.

In our forthcoming four-part series, we will delve into various aspects of utilizing CIPP technology, with a focus on the following topics:

- The Importance of CIPP and its Benefits.

- Welding Techniques for CIPP and Implementation.

- Ensuring Quality Control in CIPP Applications.

- The Difference in Main Line CIPP and Laterals

The deteriorating state of wastewater systems in North America and Europe, along with the growing volume of wastewater worldwide, have resulted in the rise of pipes bursting and the overflow of wastewater outside of the pipe. The majority of pipes are buried underground, which may result in expensive repairs requiring excavating roadways and leading to major traffic delays for many days.

The concept of lining existing pipelines with a flexible material impregnated with resin was first explored in the 1950s. Early experiments focused on using fiberglass-reinforced materials as liners. The primary motivation was to find a less disruptive and more cost-effective method for rehabilitating aging sewer and water pipelines.

In the 21st century, CIPP technology continued to advance with improvements in liner materials, resin formulations, and installation techniques. It also found applications in rehabilitation projects for larger-diameter pipelines, stormwater systems, and other critical infrastructure. The technology’s versatility and ability to extend the life of pipelines made it a valuable asset for addressing the challenges of aging infrastructure.

Today, approximately 50% of all damaged pipes are being repaired using CIPP technology. In the U.S., trenchless technology continues an upward growth trend. It has captured nearly half of the $3.4 billion market for sewer line rehabilitation and about an eighth (12.9%) of the $1.5 billion spent on repairing potable water pipes, according to the 15th Annual Municipal Infrastructure Survey conducted by Underground Construction (Oildom Publishing Co., Houston, Texas).

Trenchless pipe relining is a popular technique for repairing damaged or clogged sewer lines, water lines where the pipes are pre-fabricated at the manufacturing facility and are pre cut and welded to form the tube, the liner goes through the wet-out process, where the line is saturated with a polyester, vinyl ester, or epoxy resin. The line is then transported using a refrigerated truck to the job site and is deployed at the job site utilizing steam, hot water or UV to form the shape of the damaged pipe, making it both more economical and effective.

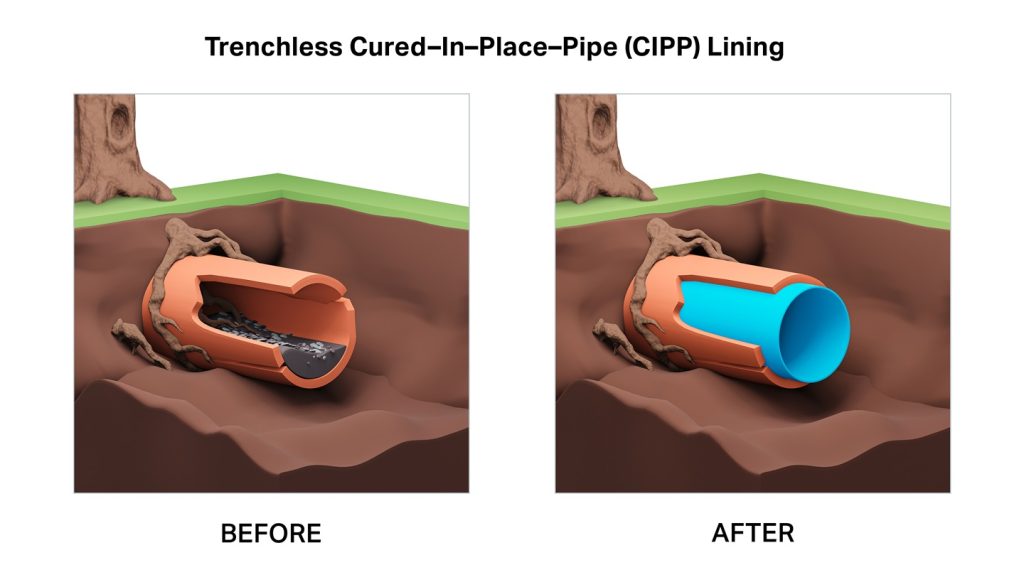

The core principle behind CIPP involves inserting a flexible liner, often composed of materials like polyester, fiberglass, or felt, into the damaged or compromised pipe. Once in position, the liner is impregnated with a thermosetting resin that, upon curing, hardens to create a new, structurally sound pipe within the existing one.

CIPP typically consists of a resin-impregnated felt or fiber sleeve. With the resin in an uncured state, it forms a flexible, conformable tube that can be inserted into a damaged pipe. Some sleeves are manufactured inside out and are inverted as they are pushed into the existing pipe via air or water pressure.

Cross Section of a damaged pipe (before), and after rehabilitation using CIPP (After) 1

The CIPP technology was developed as a solution to the challenges posed by traditional pipeline repair and replacement methods, which often involve disruptive and costly excavation. CIPP offers several benefits, including:

1. Cost Savings: CIPP eliminates or significantly reduces the need for extensive digging, resulting in reduced labor and equipment costs associated with excavation.

2. Minimal Disruption: The non-disruptive nature of CIPP means that road closures, traffic disturbances, and disruptions to daily activities are minimized, making it ideal for urban areas.

3. Environmental Considerations: CIPP reduces the environmental impact by minimizing soil disturbance, energy consumption, and emissions from construction equipment. It also extends the lifespan of existing infrastructure, reducing the need for new material production.

4. Versatility: CIPP can be used on various types of pipes, including those made of clay, concrete, cast iron, PVC, and more. This versatility makes it suitable for a wide range of pipeline rehabilitation projects.

5. Structural Reinforcement: The cured resin inside the liner not only seals leaks and prevents infiltration but also reinforces the structural integrity of the pipeline.

6. Speed of Implementation: CIPP projects are often completed faster than traditional methods due to reduced preparation and construction time, minimizing service interruptions.

E Squared has been working closely with all the major CIPP pipe manufacturers, along with the TPU vendors, felt and non-woven manufacturers across the world, and the leading manufacturers of welding and sewing machines, to ensure that we have the right solution for your application. Our Research and Development facility at Hillside, New Jersey, is working on new development projects, including high-pile knits, TPO coatings and hybrid fleece. E Squared’s dedication in the CIPP industry can be seen with the opening of our new manufacturing facility in Bluefield, VA which is dedicated to manufacturing coated felts for CIPP applications.

To learn more our E Squared FlexPipe CIPP Products visit www.e2techtextiles.com/industries/cured-in-place-pipe/ or call +1-908-249-4376.

Reference