Geomembranes are low-permeability synthetic membrane liners or barriers formed into sheets used as a barrier to control or mitigate fluid and gas migration into the soil. Common applications of geomembranes include landfills, pond liners, dams, erosion control, sediment control, landfill liners, landfill covers, mining industry among other applications providing a barrier between the environment and possible contaminants.

Geomembranes are part of the larger family called Geosynthetics, if you break it down, geo means earth or soil, whereas synthetic is man made. Geosynthetics are defined as “planar, polymeric (synthetic or natural) material used in contact with soil/rock and/or any other geotechnical material for filtration, drainage, separation, reinforcement, protection, sealing, and packing.” [1] Geosynthetics have two major classifications, permeable membranes such as geotextiles, geogrids and geocells and impermeable membranes such as geomembranes and geosynthetic clays (GCL).

Geomembranes may be reinforced with fabrics or they may be non-reinforced films, they could vary in thickness between 20-60 mil, but essentially needs to have certain properties like low -permeability, low gas and water vapor transmission rate, chemical resistant, puncture resistant and have good weatherability. Unreinforced geomembranes are cost-effective and relatively easy to install; they provide excellent chemical and UV resistance, and are typically used in less demanding applications such as secondary containment liners for spills and leaks, covers for wastewater treatment facilities, and decorative water features. They are also used in lining systems for temporary or short-term projects, such as temporary storage ponds or construction sites.

Reinforced geomembranes offer excellent durable performance and are cost-effective, making them an ideal choice for a wide range of civil and environmental engineering applications. The reinforcing layer of geotextile fabric helps to distribute and resist any loading on the liner surface, increasing the compressive and tensile strength of the liner. This makes reinforced geomembranes highly suitable for use in environments where substrates are uneven or settlement-prone.

To meet the above requirements, Geomembranes are commonly made from polymers such as PVC, EIA, HDPE, LLDPE and others via manufacturing methods known as extrusion, calendaring, or spread coating. Understanding the properties of the polymers used to create a geomembrane is necessary for its designs and specifications to meet the project requirements. For instance, the degree of flexibility of the polymers can change greatly from one to another affecting the installation process, the service life of the geomembrane can be greatly improved by adding antioxidants, carbon black and other UV packages to help with weatherability. Geomembranes that are formulated for exposed applications have a typical service life of 30 years, but there are many examples where they are in operation for beyond 30 years with little to no loss in its physical properties.

Many geomembranes are specifically designed for buried applications, where they are protected from the elements like UV degradation, freezing, wind uplift and damage from animal or humans’ intrusion thus extending its service life to well beyond 100 years. Also, a thicker material also extends the anticipated service life.

The most common polymeric geomembranes are HDPE, LLDPE and PVC, with EIA geomembranes (which is an alloy of PVC resin with high molecular weight ketone ethylene ester (KEE) solid plasticizer) gaining popularity because of its versatile nature.

Geomembrane Type |

Abbreviation |

Polymer Type |

Typical Properties |

High density Polyethylene |

HDPE |

Thermoplastic |

|

Linear Low-density polyethylene |

LLDPE |

Thermoplastic |

|

Polyvinyl Chloride |

PVC |

Thermoplastic |

|

Ethylene Interpolymer Alloy |

EIA |

Thermoplastic |

|

Geomembranes serve as a crucial tool for containment purposes. They find extensive application in various industries such as agriculture, energy, mining, and construction. In agriculture, geomembranes are utilized to line silos, while in other sectors, they play a vital role in managing industrial water and waste. Moreover, geomembranes are employed as versatile solutions like portable water tanks and liners for ponds, fish ponds, canals, and dams. In the construction domain, PVC and EIA geomembranes are particularly popular for constructing canals, landfills, soil remediation sites, wastewater lagoon liners, and tank linings. EIA geomembranes also serve as protectors for Expanded Polystyrene (EPS) wraps used in road construction on roads and highways. Regardless of the application, the primary objectives of geomembranes are to ensure containment of liquids, solids, or gas contaminants, prevent erosion, leakage, and protect against harmful UV rays and other natural elements

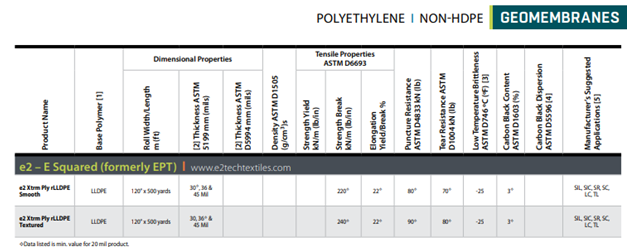

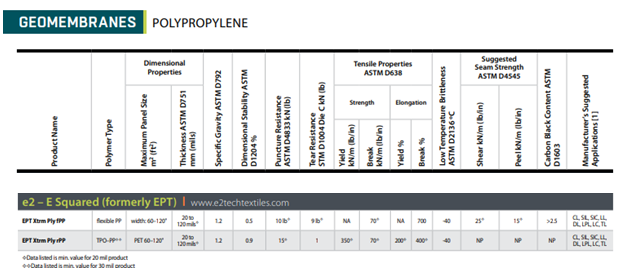

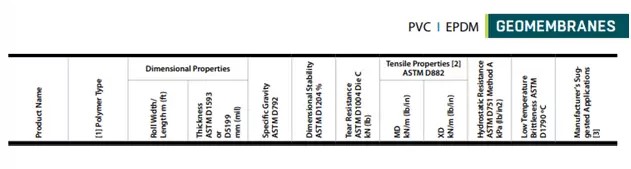

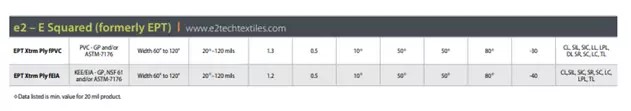

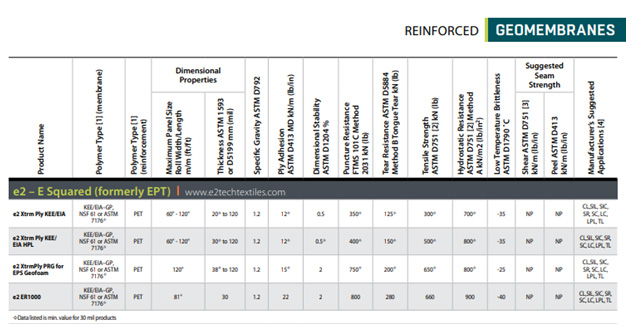

At E Squared, we produce geomembranes in both smooth and textured finish, with or without reinforcements and varying colors for a wide variety of buried and exposed applications. Below is a list of our products available: